Machine Tool Technology Specialist

On-Demand Technical Intelligence for Complex Machinery

“Your Industry’s Silver Bullet Troubleshooter”

Intro:

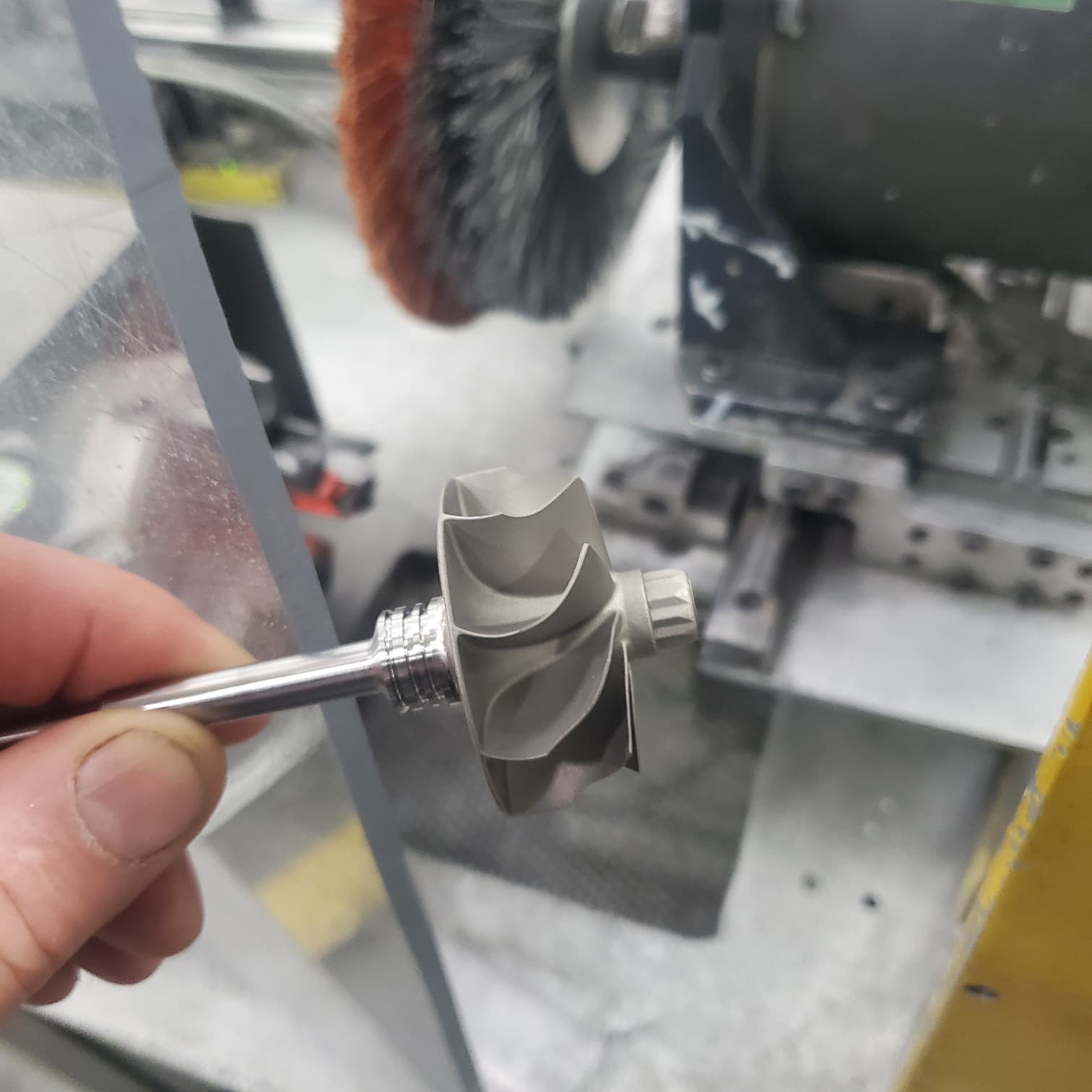

I’m not a repair mechanic. I’m a solution finder who analyzes how machines and processes behave — and why they fail. My work blends mechanical, electrical, servo, hydraulic, and control logic analysis with real-world production behavior.

Whether onsite or supporting remotely, I help teams understand what’s happening inside their equipment and what must change to improve reliability, scrap rate, and cycle time.

When downtime is expensive and the symptoms don’t tell the whole story, I provide clear, structured technical insight and a fast path back to reliable production.

Key roles:

“How I Work”

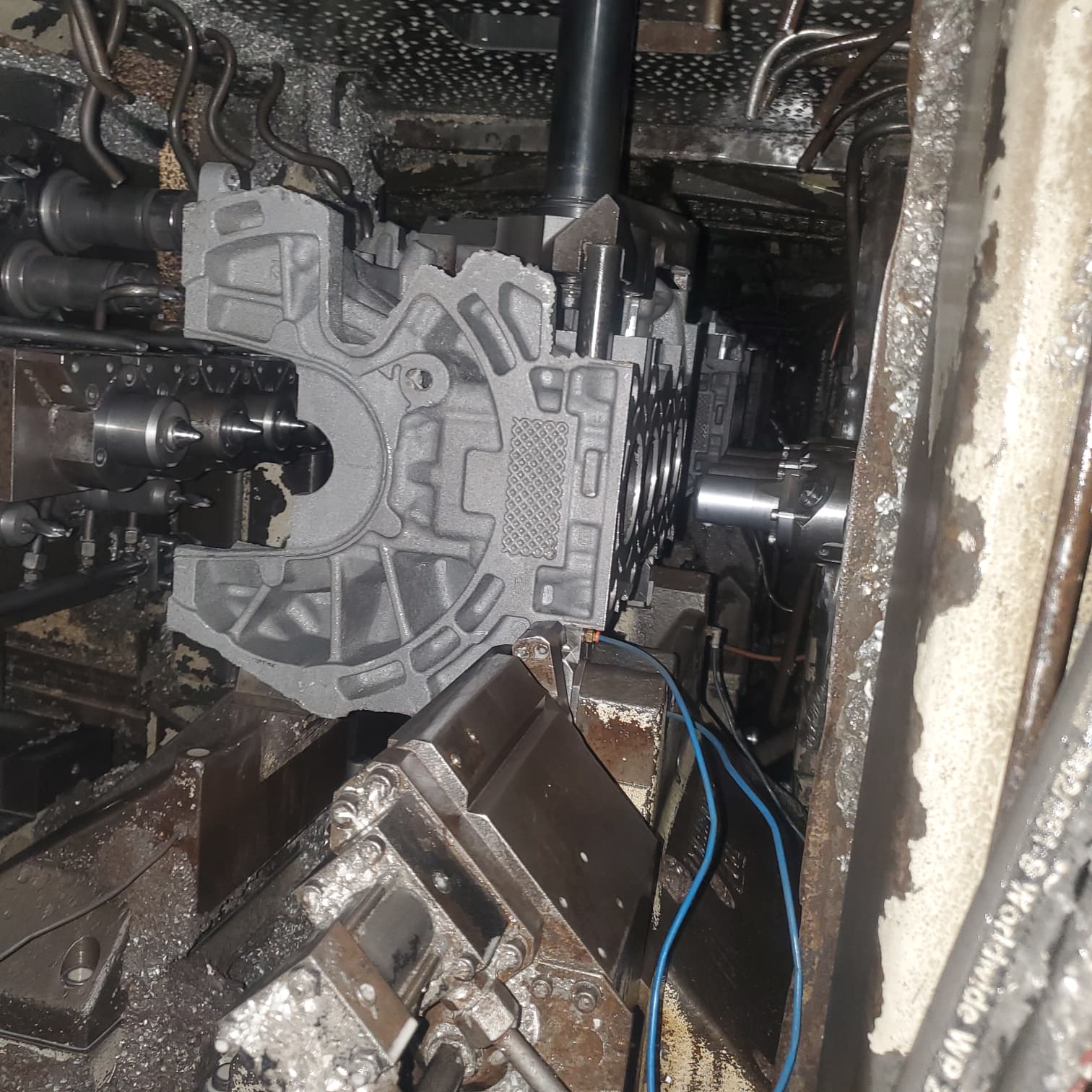

I support critical machines and production processes where guesswork isn’t acceptable. My approach combines accurate diagnostics, process optimization, and practical improvements that drive measurable gains in quality, reliability, and output.

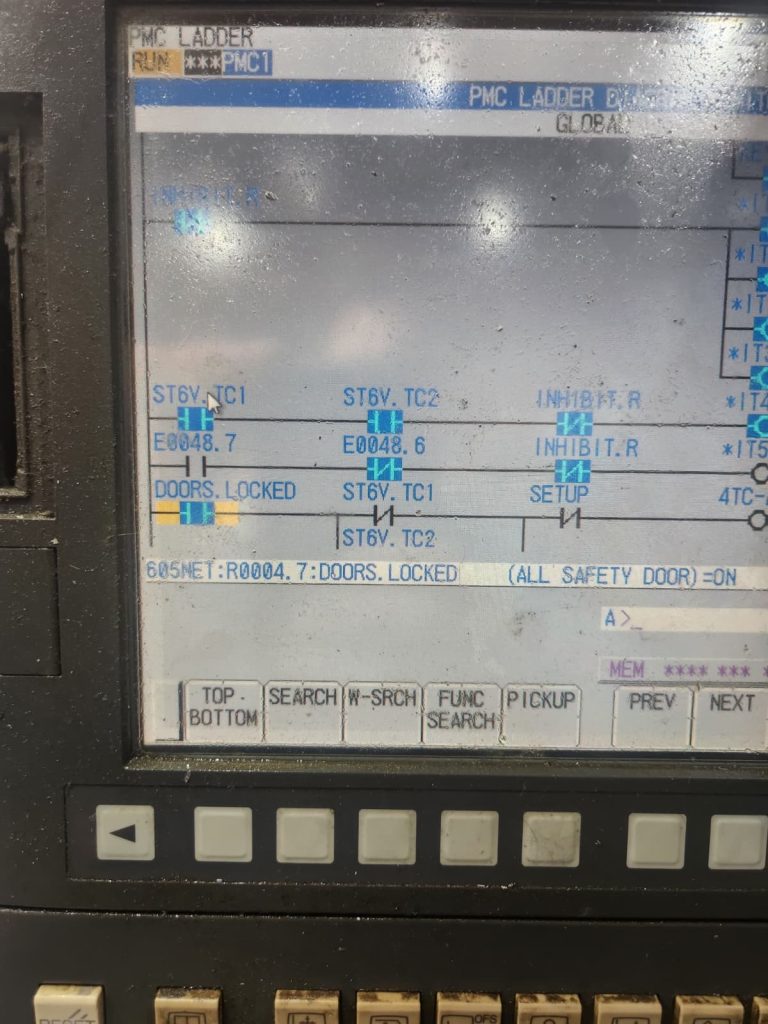

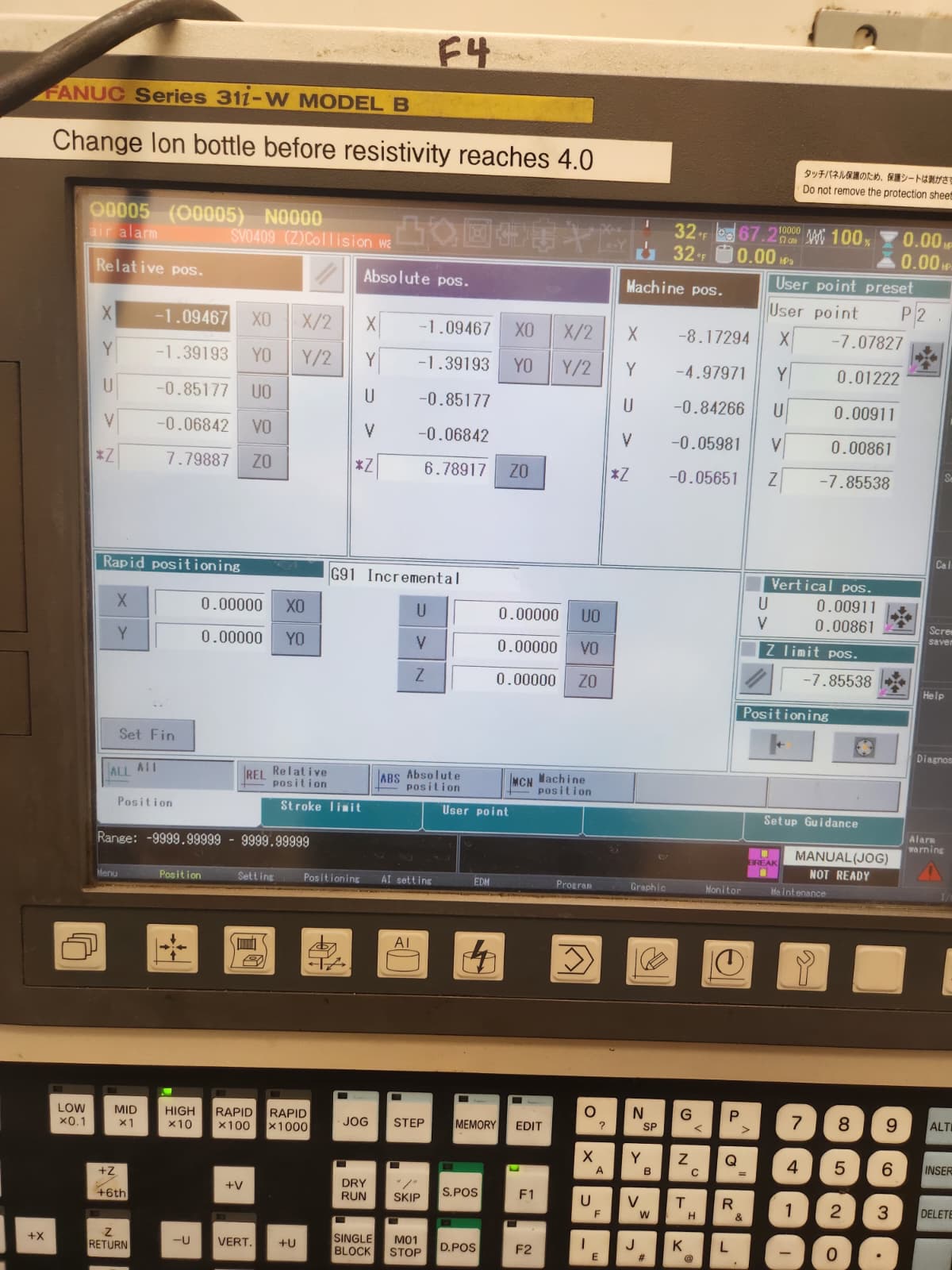

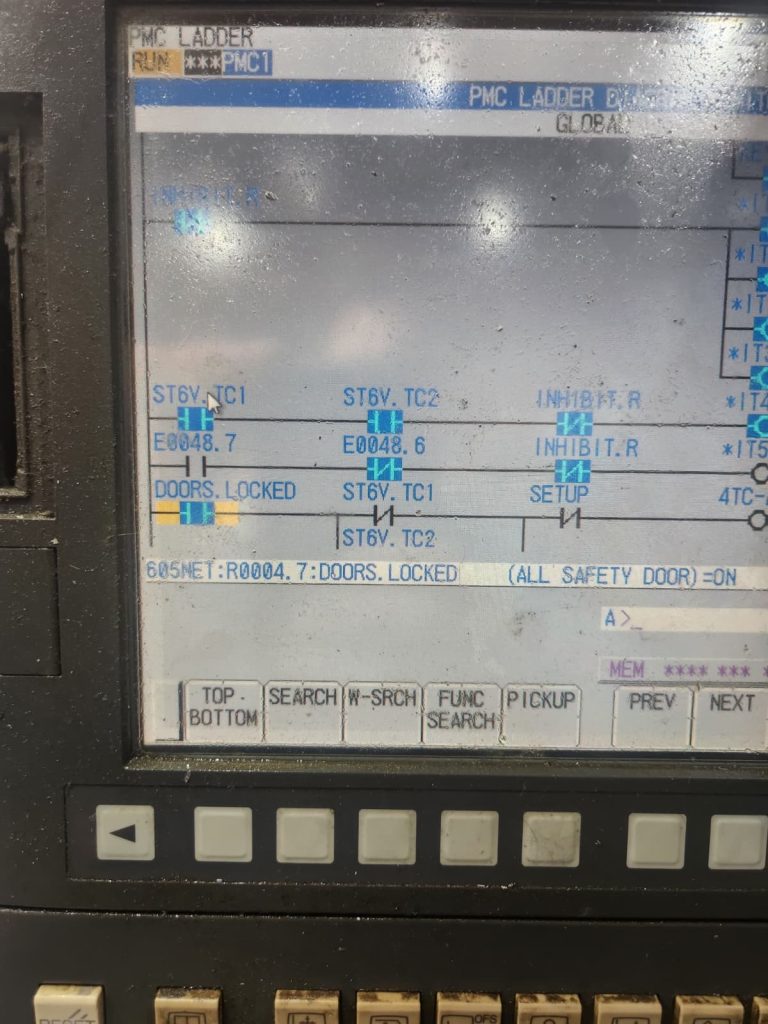

Remote Diagnostics for CNC & Automation

Live, on-demand technical intelligence to quickly identify likely failure points and next steps—without waiting for someone to travel.

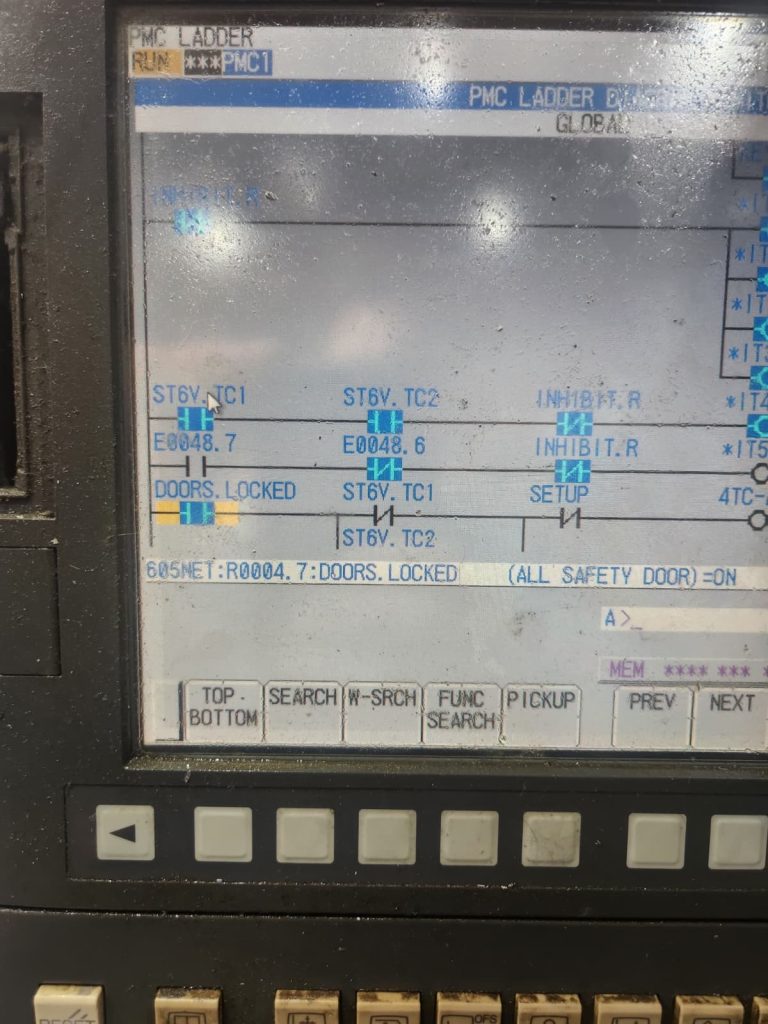

Industrial Troubleshooting & Root-Cause Analysis

Systematic investigation of electrical, mechanical, servo, control, and process issues to stop repeat failures.

Legacy Machine Tool Recovery

Support for older CNC controls, drives, and custom or “one-off” systems that newer techs won’t touch.

Machine Tool & Automation Advisory

Guidance for engineering, maintenance, and leadership teams on repair vs. replace decisions, risk reduction, and uptime strategy.

Process & Uptime Optimization

Recommendations to stabilize critical machines, reduce unplanned downtime, and improve reliability over time.

The Two-Layer Model

Machine failures rarely come from a single component. They usually come from disruptions in the energy moving through the tool—electrical, hydraulic, pneumatic, mechanical, or thermal. To handle this complexity, I use a two-layer support structure that separates fast symptom capture from deeper engineering analysis.

Layer 1 – Provide immediate direction — onsite or remotely

Where I analyze symptoms, gather evidence, interview operators, and debug the situation to understand the true behavior of the system. This can happen remotely or onsite. The goal is clarity: knowing what’s happening, why it’s happening, and what needs attention first.

Layer 2 – Improvement & Optimization (Lasting Gains)

Once the root cause is understood, I focus on improving the system so the issue doesn’t return — and often, this includes reducing scrap, improving cycle time, refining motion paths, and increasing reliability.

Layer 1 finds the truth

Layer 2 makes the system better than before

Equipment and Technology Range

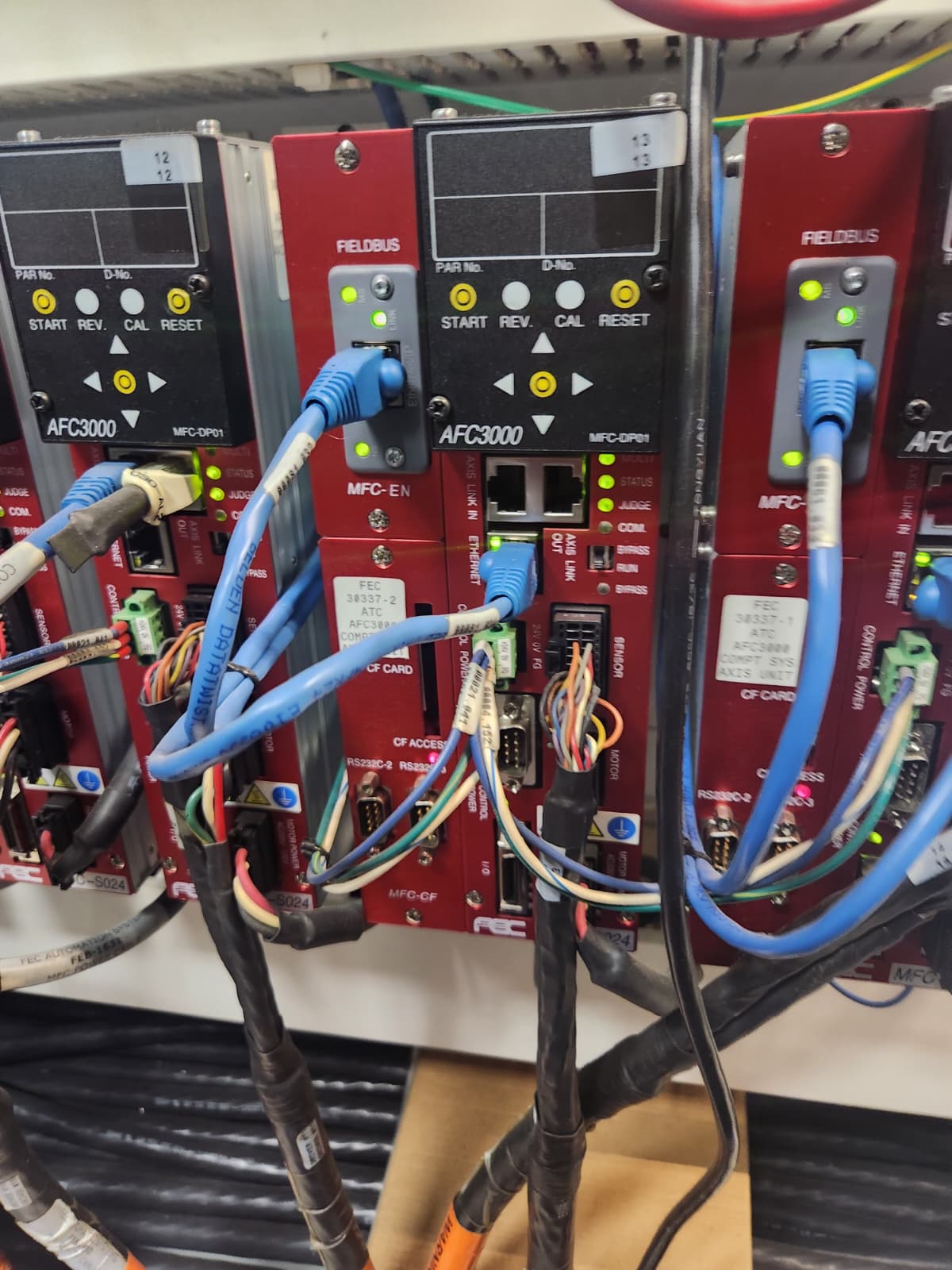

• Analog drives and early NC controls

• First-generation PLC and relay-based systems

• 1990s–2000s hybrid control platforms

• Modern assembly, digital CNC and servo systems

• Hydraulic and pneumatic legacy equipment

• Rebuilt, retrofitted, or heavily modified machines

If it moves, cuts, presses, grinds, lifts, forms, or measures, it can be diagnosed and improved using this approach.

Why Companies Call Me

I’m often called in when other attempts have failed, parts have been replaced without solving the issue, or chronic problems keep returning. My role is to bring structure, experience, and cross-discipline insight to the situation—reducing downtime, avoiding unnecessary repairs, and improving the long-term stability of your equipment.

Ready to reduce downtime and get clear direction?